Expand for details

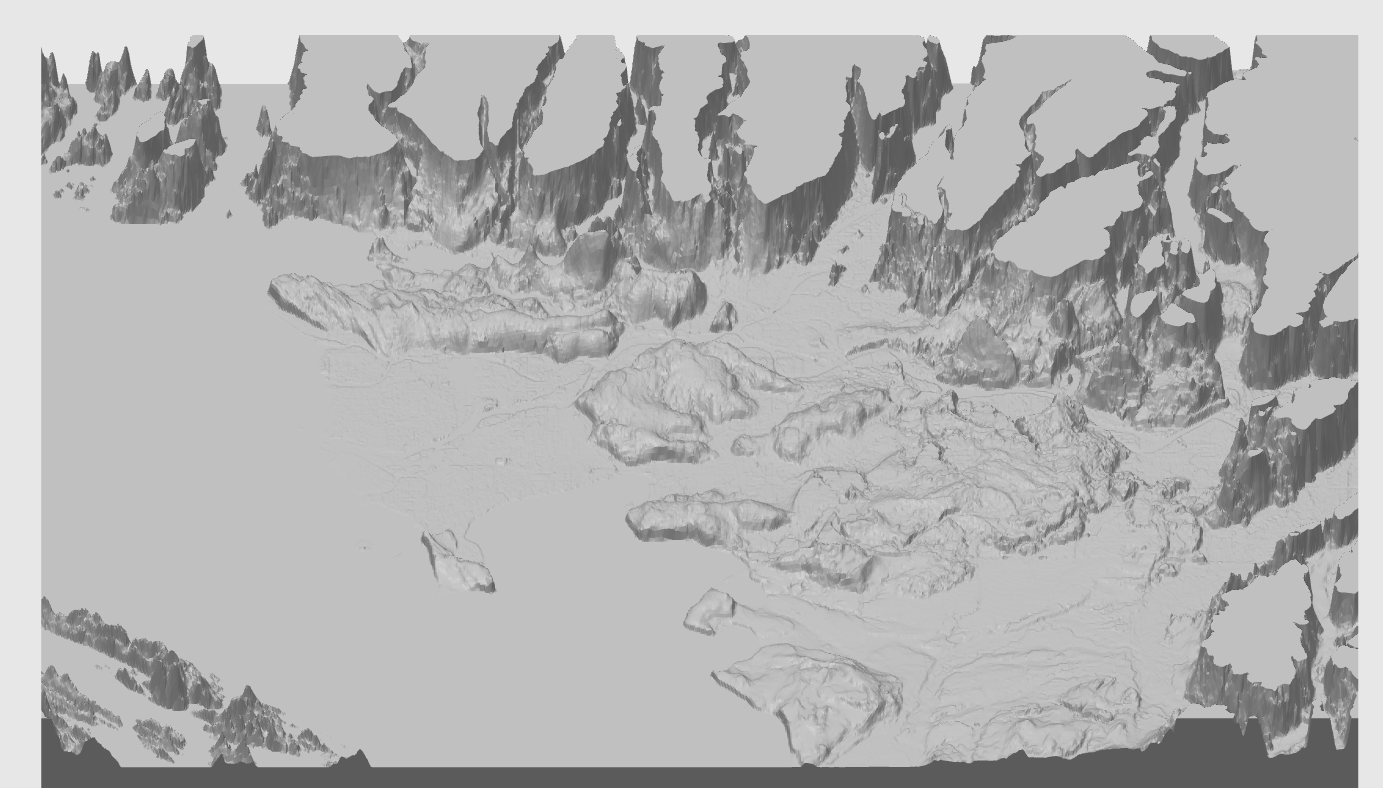

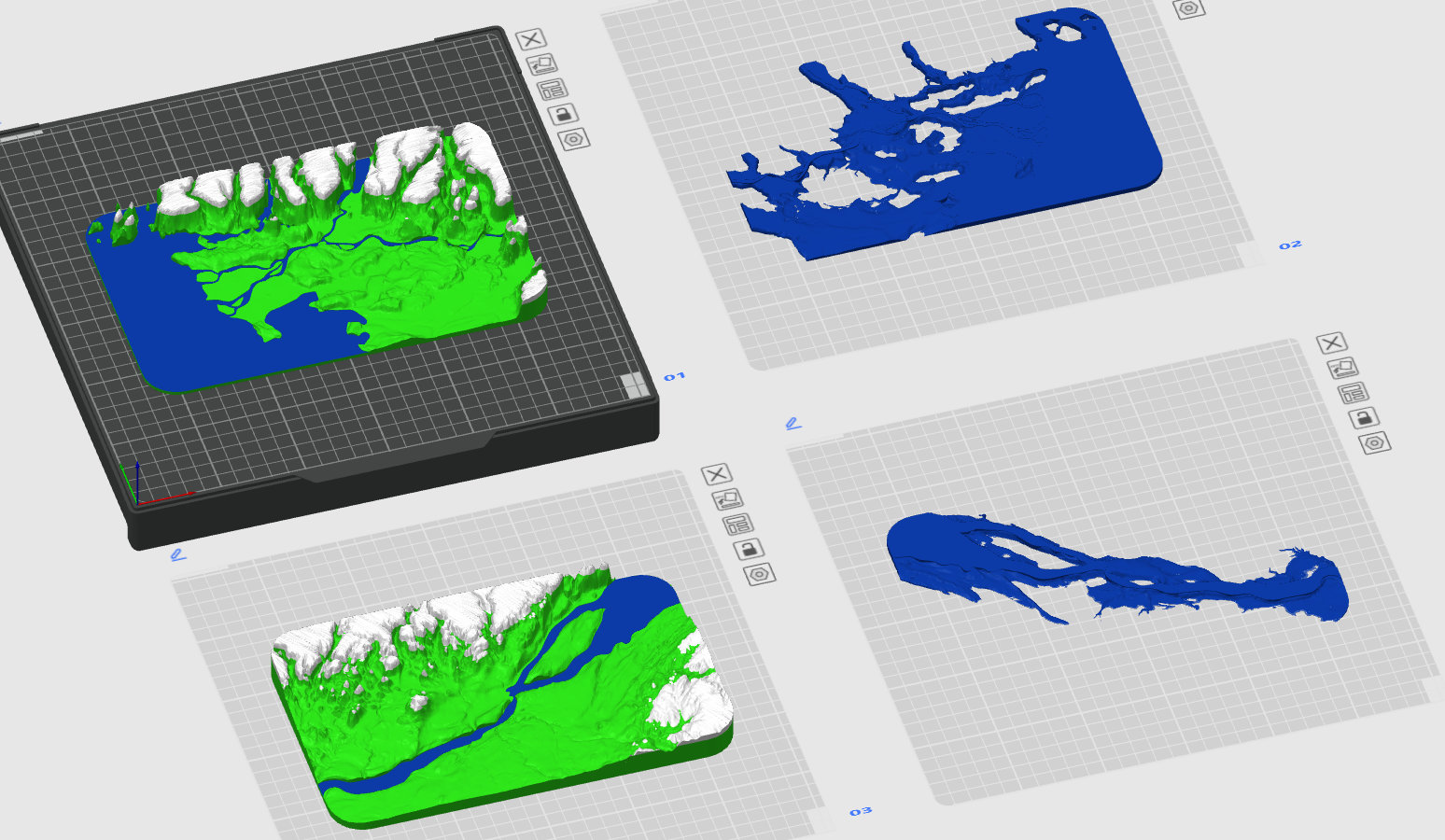

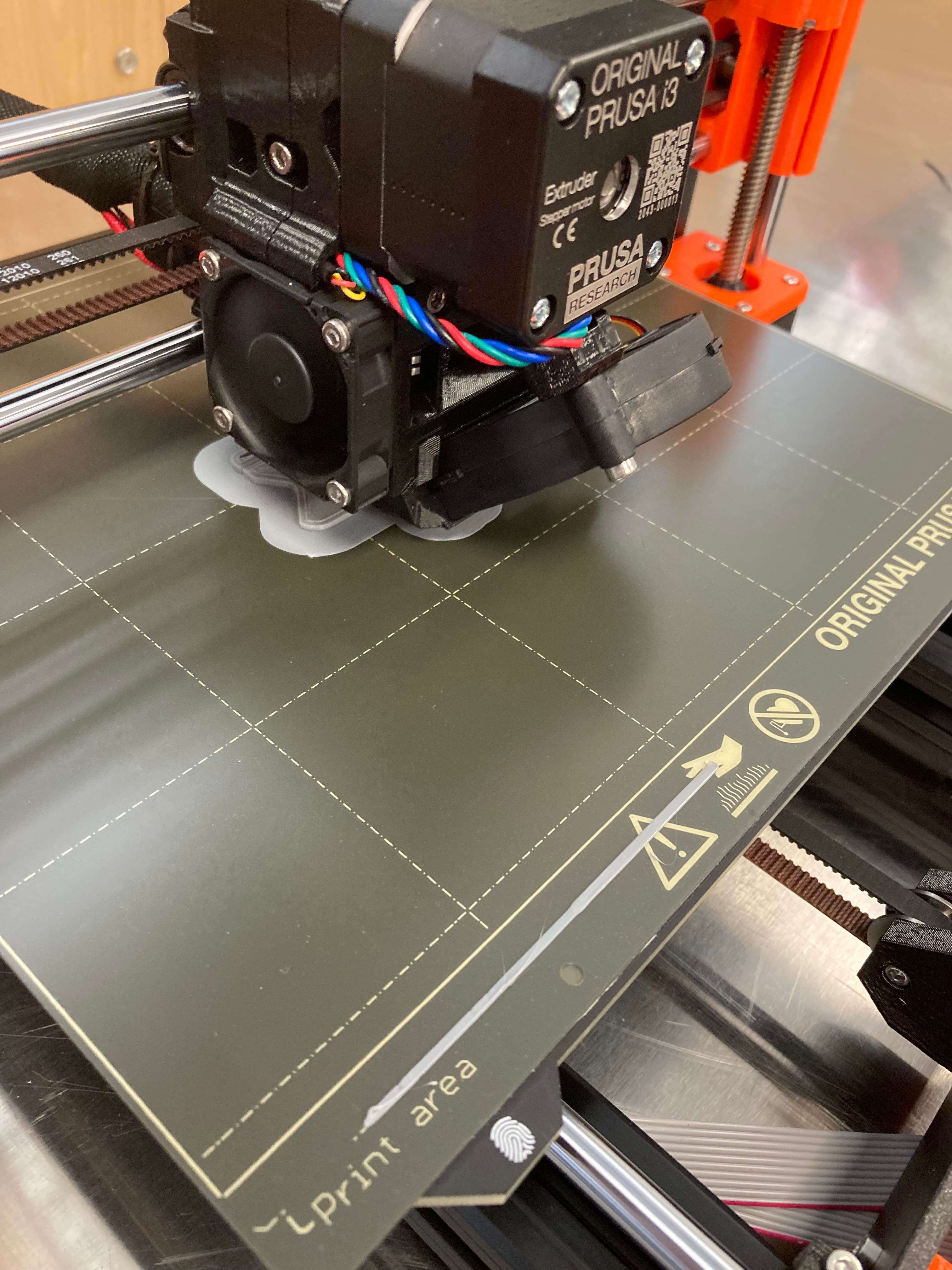

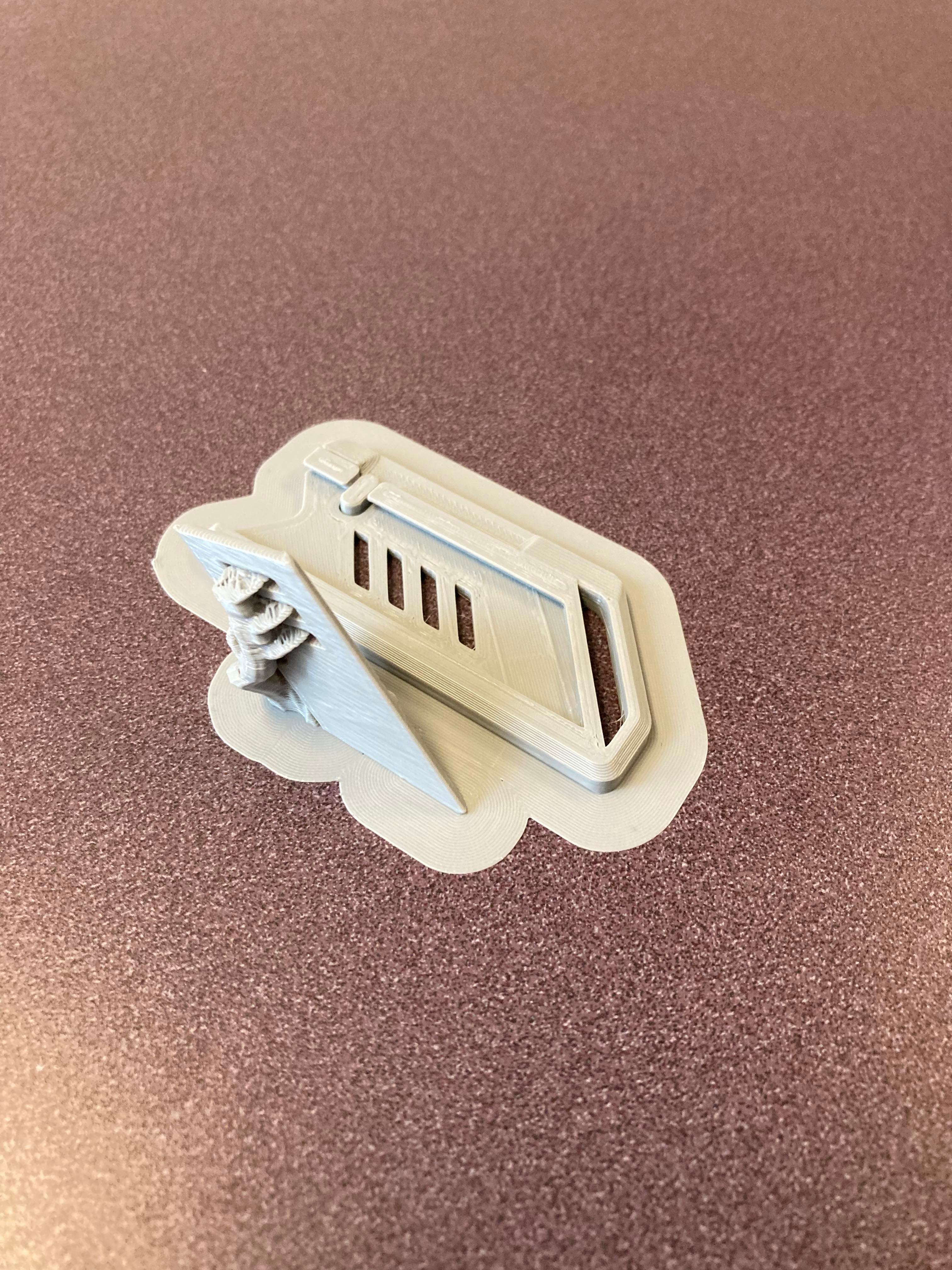

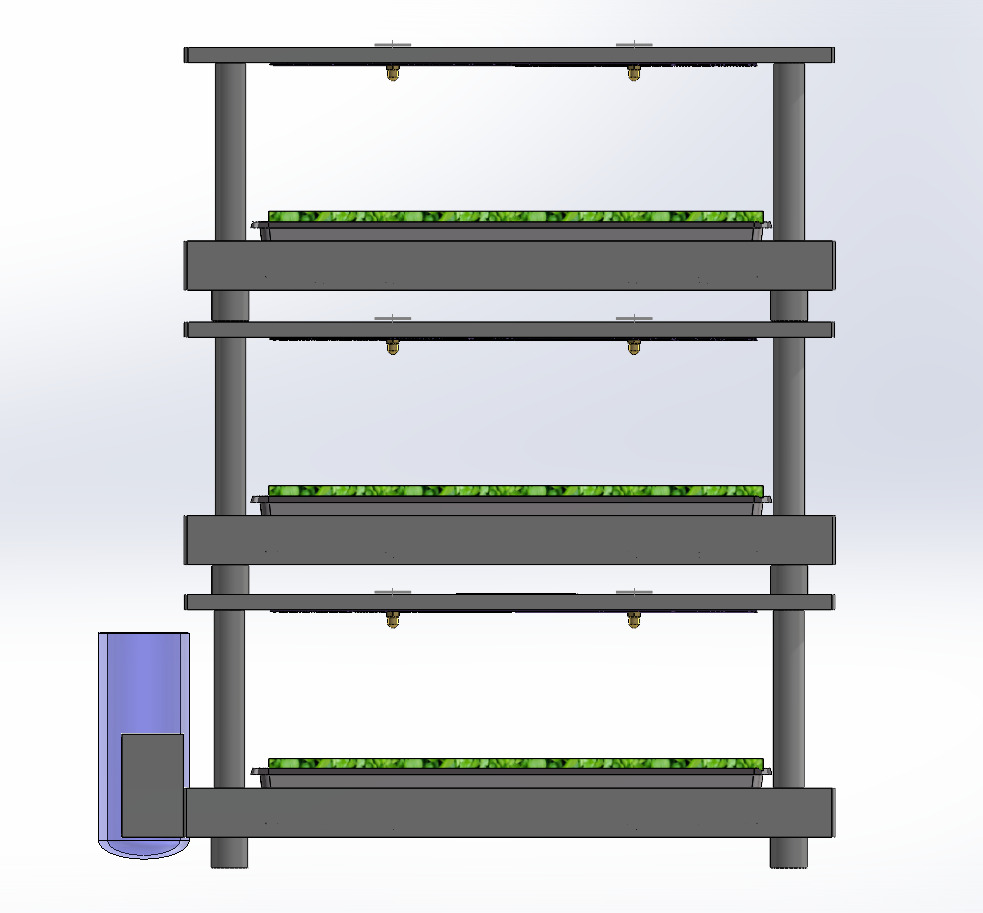

For my Additive Manufacturing Design project, our team built a workflow to visualize climate change data physically.

The goal was to take abstract data and turn it into a tangible 3D model that anyone could hold.

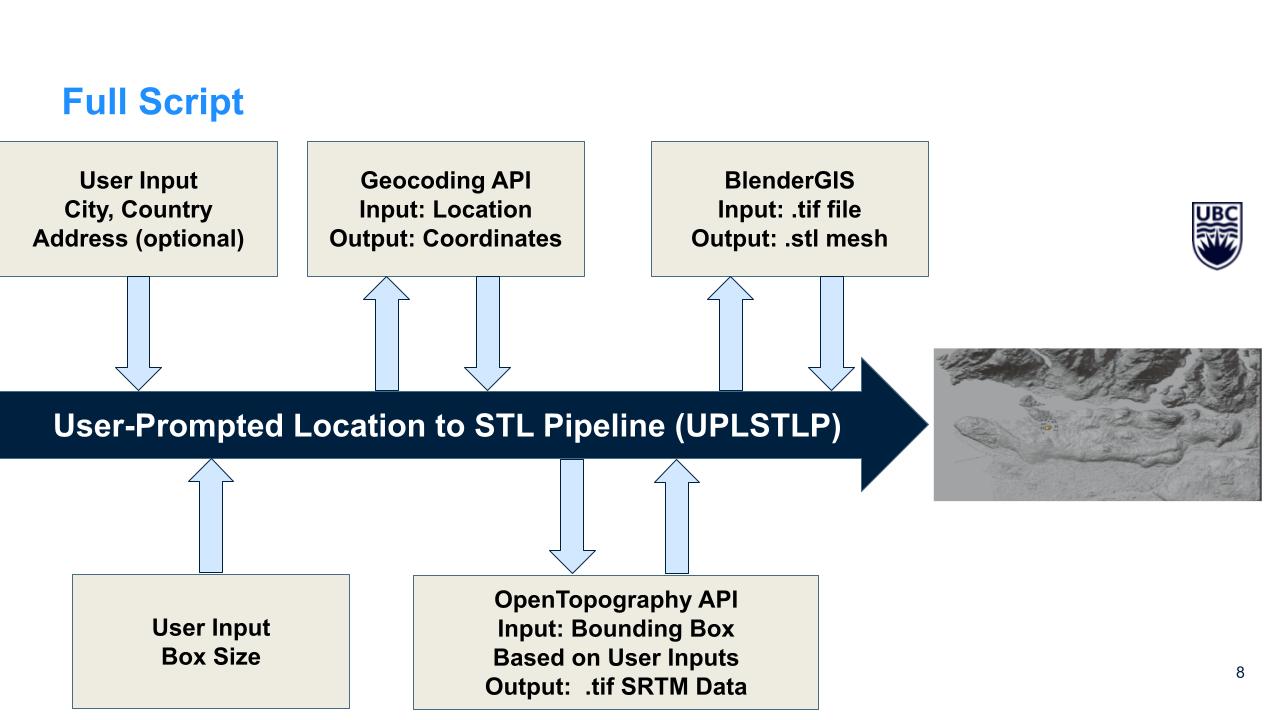

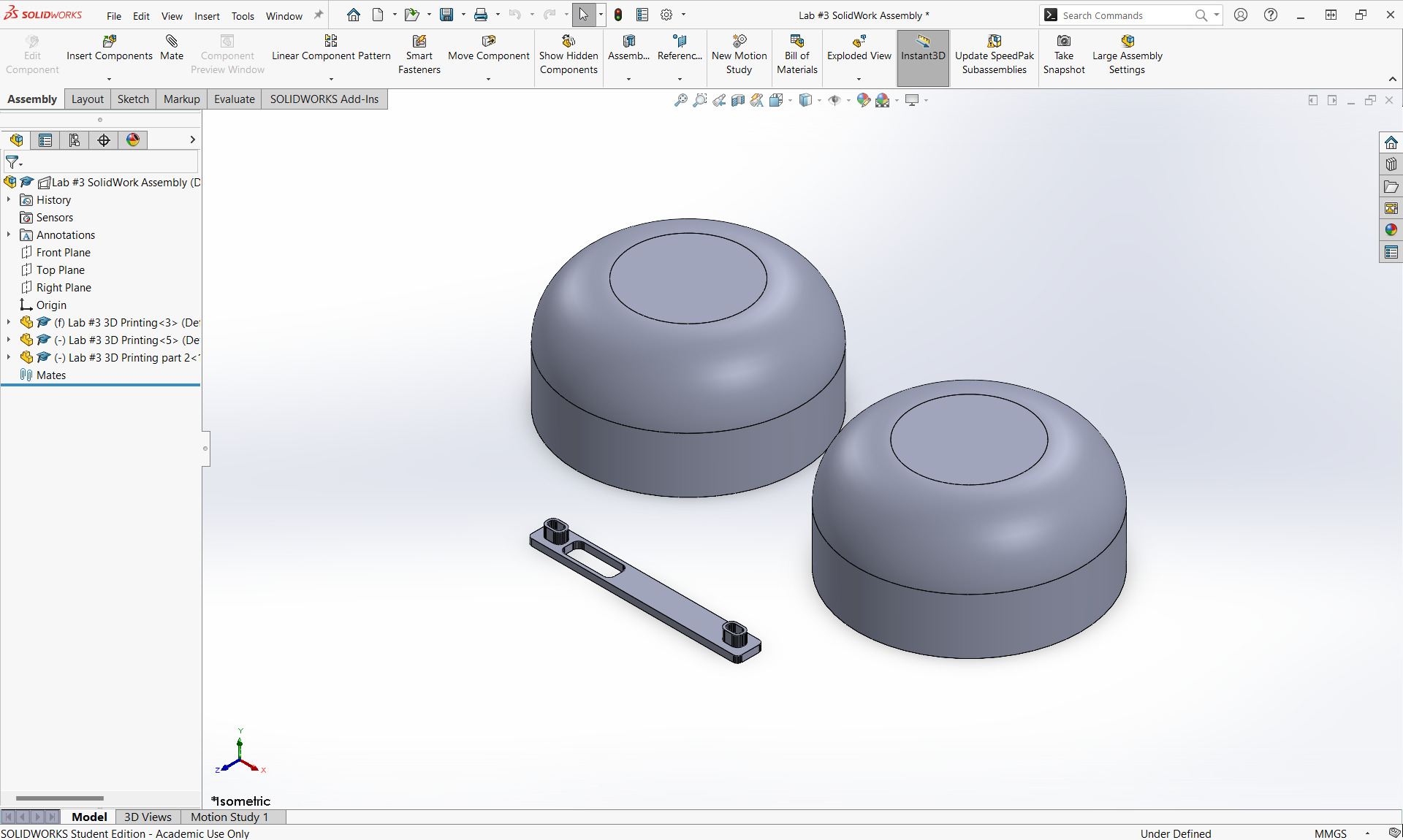

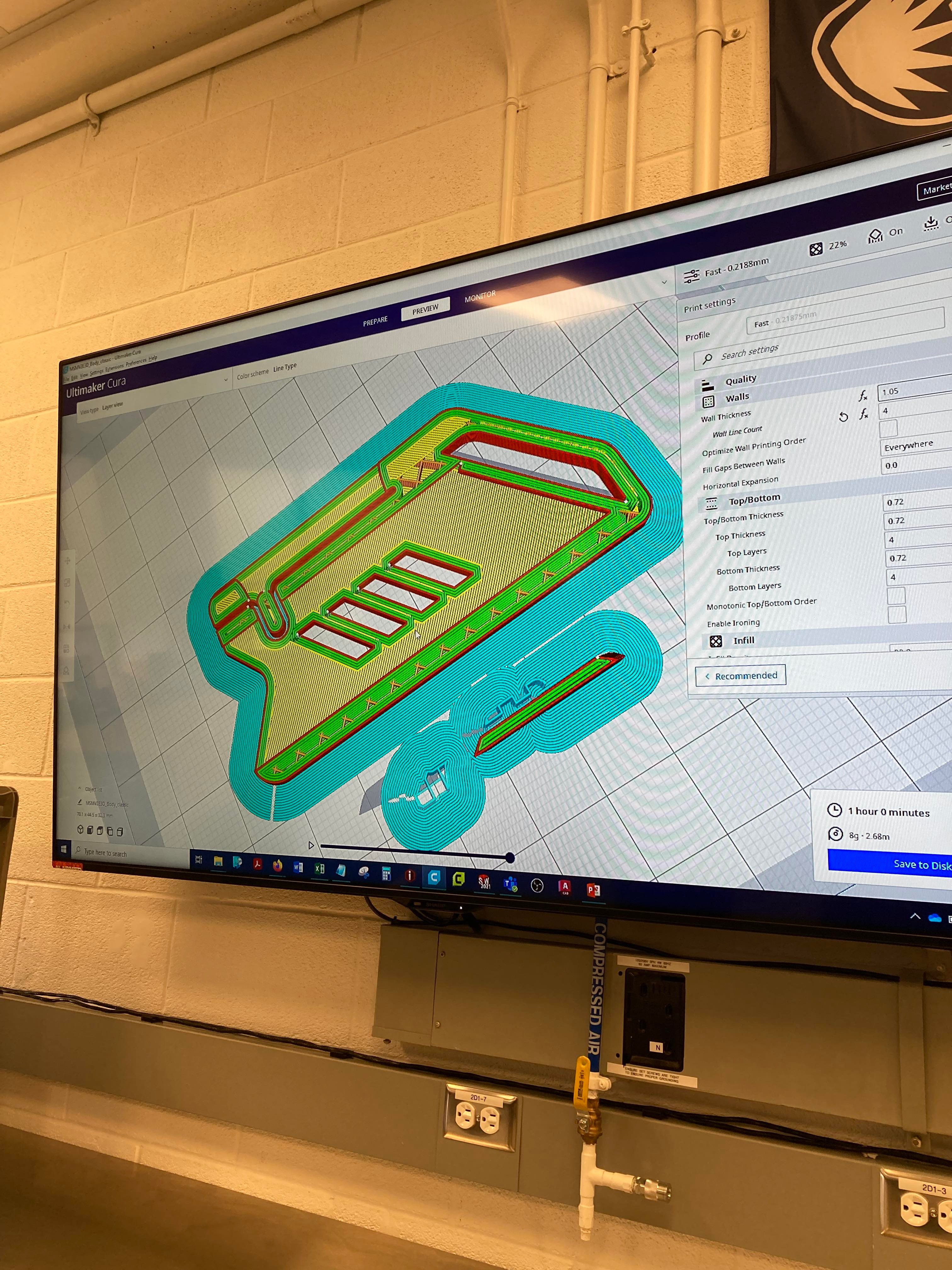

My role focused on the software pipeline and fabrication. We automated the process of grabbing Digital Elevation Model (DEM) data

from NASA/Google APIs, processing the heightmaps in Blender to remove noise, and generating printable STL files.

A key technical challenge was designing the "water" inserts. I developed a method to generate a separate, boolean-subtracted

volume for the ocean that perfectly mated with the terrain mesh. This allowed us to print the terrain in green and the water

in blue using filament swaps, creating a clear, educational visualization of how rising sea levels impact specific coastal cities.

.jpg)

.jpg)